Rinaudo M. Main properties and current applications of some polysaccharides as biomaterials. Polym Int. 2008;57:397–430.

Iijima K, Hashizume M. Application of polysaccharides as structural materials. Trends Glycosci Glycotechnol. 2015;27:67–79.

Klemm D, Heublein B, Fink HP, Bohn A. Cellulose: fascinating biopolymer and sustainable raw material. Angew Chem Int Ed. 2005;46:3358–93.

Rinaudo M. Chitin and chitosan: properties and applications. Prog Polym Sci. 2006;31:603–32.

Burdick JA, Prestwich GD. Hyaluronic acid hydrogels for biomedical applications. Adv Mater. 2011;23:H41–56.

Sugahara K, Mikami T, Uyama T, Mizuguchiz S, Nomuraz K, Kitagawa H. Recent advances in the structural biology of chondroitin sulfate and dermatan sulfate. Curr Opin Struc Biol. 2003;13:612–20.

Yui N, Okano T, Sakurai Y. Inflammation responsive degradation of crosslinked hyaluronic acid gels. J Control Release. 1992;22:105–16.

Sintov A, Di–Capua N, Rubinstein A. Cross-linked chondroitin sulphate: characterization for drug delivery purposes. Biomaterials. 1995;16:473–78.

Decher G. Fuzzy nanoassemblies: toward layered polymeric multicomposites. Science. 1997;277:1232–7.

Hammond PT. Form and function in multilayer assembly: new applications at the nanoscale. Adv Mater. 2004;16:1271–93.

Sukhishvili SA. Responsive polymer films and capsules via layer–by–layer assembly. Curr Opin Colloid Interface Sci. 2005;10:37–44.

Fujie T, Okamura Y, Takeoka S. Ubiquitous transference of a free-standing polysaccharide nanosheet with the development of a nano-adhesive plaster. Adv Mater. 2007;19:3549–53.

Gribova V, Auzely–Velty R, Picart C. Polyelectrolyte multilayer assemblies on materials surfaces: from cell adhesion to tissue engineering. Chem Mater. 2011;24:854–69.

Caridade SG, Monge C, Gilde F, Boudou T, Mano JF, Picart C. Free–standing polyelectrolyte membranes made of chitosan and alginate. Biomacromolecules. 2013;14:1653–60.

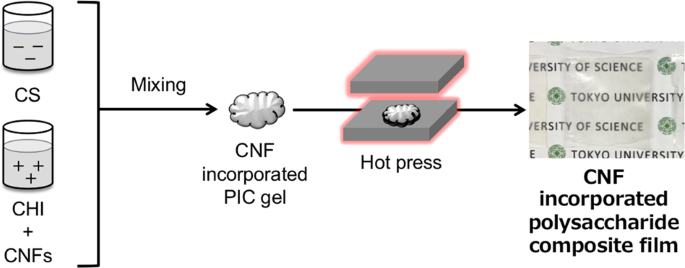

Hashizume M, Kobayashi H, Ohashi M. Preparation of free–standing films of natural polysaccharides using hot press technique and their surface functionalization with biomimetic apatite. Colloids Surf B. 2011;88:534–8.

Hashizume M, Ohashi M, Kobayashi H, Tsuji Y, Iijima K. Free–standing polysaccharide composite films: improved preparation and physical properties. Colloids Surf A. 2015;483:18–24.

Hashizume M, Murata Y, Iijima K, Shibata T. Drug loading and release behaviors of freestanding polysaccharide composite films. Polym J. 2016;48:545–50.

Iijima K, Kimura T, Sato R, Takahashi T, Hashizume M. Kinetic analysis of molecular permeabilities of free–standing polysaccharide composite films. Macromol Chem Phys. 2017;218:1600391.

Iijima K, Tsuji Y, Kuriki I, Kakimoto A, Nakaido Y, Ninomiya R, et al. Control of cell adhesion and proliferation utilizing polysaccharide composite film scaffolds. Colloids Surf B. 2017;160:228–37.

Iijima K, Suzuki A, Hashizume M. Preparation of swellable and highly operable composite films made of polysaccharide and supporting substrates. Kobunshi Ronbunshu. 2018;75:195–202.

Huanga ZM, Zhangb YZ, Kotakic M, Ramakrishna S. A review on polymer nanofibers by electrospinning and their applications in nanocomposites. Compos Sci Technol. 2002;63:2223–53.

Paul DR, Robeson LM. Polymer nanotechnology: nanocomposites. Polymer. 2008;49:3187–204.

Sanchez C, Julián B, Belleville P, Popall M. Applications of hybrid organic–inorganic nanocomposites. J Mater Chem. 2005;15:3559–92.

Habibi Y, Lucia LA, Rojas OJ. Cellulose nanocrystals: chemistry, self-assembly, and applications. Chem Rev. 2010;110:3479–500.

Isogai A, Saito T, Fukuzumi H. TEMPO–oxidized cellulose nanofibers. Nanoscale. 2011;3:71–85.

Mial C, Hamad WY. Cellulose reinforced polymer composites and nanocomposites: a critical review. Cellulose. 2013;20:2221–62.

Qua EH, Hornsby PR, Sharma HSS, Lyons G, McCall RD. Preparation and characterization of poly (vinyl alcohol) nanocomposites made from cellulose nanofibers. J Appl Polym Sci. 2009;113:2238–47.

Qu P, Gao Y, Wu GF, Zhang LP. Nanocomposites of poly(lactic acid) reinforced with cellulose nanofibrils. BioResources 2010;5:1811–23.

Hagiwara Y, Putra A, Kakugo A, Furukawa H, Gong JP. Ligament–like tough double-network hydrogel based on bacterial cellulose. Cellulose. 2010;17:93–101.

Yang J, Zhao JJ, Xu F, Sun RC. Revealing strong nanocomposite hydrogels reinforced by cellulose nanocrystals: insight into morphologies and interactions. ACS Appl Mater Interfaces. 2013;5:12960–7.

Ansari F, Skrifvars M, Berglund L. Nanostructured biocomposites based on unsaturated polyester resinand a cellulose nanofiber network. Compos Sci Technol. 2015;117:298–306.

Nakayama A, Kakugo A, Gong JP, Osada Y, Takai M, Erata T, et al. High mechanical strength double-network hydrogel with bacterial cellulose. Adv Funct Mater. 2004;14:1124–8.

Srithongkaham S, Vivitchanont L, Krongtaew C. Starch/cellulose biocomposites prepared by high-shear homogenization/compression molding. J Mater Sci Eng B. 2012;2:213–22.

Wu T, Farnood R, O’kelly K, Chen B. Mechanical behavior of transparent nanofibrillar cellulose–chitosan nanocomposite films in dry and wet conditions. J Mech Behav Biomed. 2014;32:279–86.

Yadav CY, Maji PK. Synergistic effect of cellulose nanofibres and bio- extracts for fabricating high strength sodium alginate based composite bio-sponges with antibacterial properties. Carbohydr Polym. 2019;203:396–408.

Lee JH, Marroquin J, Rhee KY, Park SJ, Hui D. Cryomilling application of graphene to improve material propertiesof graphene/chitosan nanocomposites. Composites. 2013;45:682–7.

Park MJ. Synthesis and characterization of graphene oxide/carboxymethylcellulose/alginate nanocomposites blends. Carbohydr Polym. 2014;110:18–25.

Cui K, Sun TL, Kurokawa T, Nakajima T, Nonoyana T, Chen L, et al. Stretching–induced ion complexation in physical polyampholyte hydrogels. Soft Matter. 2016;12:8833–40.

ALR Pires, Motta LA, Moraes ÂM, MEM Braga. Towards wound dressings with improved properties: effects of poly(dimethylsiloxane) on chitosan–alginate films loaded with thymol and beta–carotene. Mat Sci Eng C. 2018;93:595–605.

Chen WB, Wang LF, Chen JS, Fan SY. Characterization of polyelectrolyte complexes between chondroitin sulfate and chitosan in the solid state. J Biomed Mater Res. 2005;75A:128–37.

Qua EH, Hornsby PR, Sharma HSS, Lyons G. Preparation and characterization of cellulose nanofibers. J Mater Sci. 2011;46:6029–45.

Liu D, Wu Q, Chang PR, Gao G. Self–assembled liquid crystal film from mechanically defibrillated chitosan nanofibers. Carbohydr Polym. 2011;84:686–9.

Wang H, Prendiville PL, McDonnellt PJ, Chang WV. An ultrasonic technique for the measurement of the elastic moduli of human ocrnea. J Biomech. 1996;29:1633–6.

Egorova VI. Schastlivtsevb IV, Prutc EV, Baranovc AO, Turusov RA. Mechanical properties of the human gastrointestinal tract. J Biomech. 2002;35:1417–25.

Source: Ecology - nature.com