Shannon, M. et al. Science and technology for water purification in the coming decades. Nature 452, 301–310 (2008).

Shi, Z. et al. Ultrafast separation of emulsified oil/water mixtures by ultrathin free-standing single-walled carbon nanotube network films. Adv. Mater. 25, 2422–2427 (2013).

Zhang, R.-X., Braeken, L., Luis, P., Wang, X.-L. & Van der, B. Bruggen. Novel binding procedure of TiO2 nanoparticles to thin film composite membranes via self-polymerized polydopamine. J. Memb. Sci. 437, 179–188 (2013).

Darmanin, T., De Givenchy, E. T., Amigoni, S. & Guittard, F. Superhydrophobic surfaces by electrochemical processes. Adv. Mater. 25, 1378–1394 (2013).

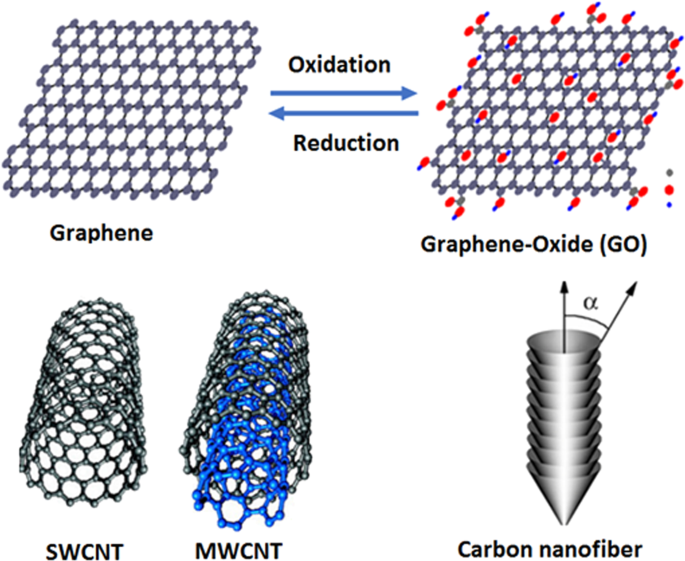

Al-anzi, B. S. & Siang, O. C. Recent developments of carbon based nanomaterials and membranes for oily wastewater treatment. RSC Adv. 7, 20981–20994 (2017).

Han, G. et al. Combination of forward osmosis (FO) process with coagulation/flocculation (CF) for potential treatment of textile wastewater. Water Res. 91, 361–370 (2016).

Ao, C. et al. Superhydrophilic graphene oxide@electrospun cellulose nanofiber hybrid membrane for high-efficiency oil/water separation. Carbohydr. Polym. 175, 216–222 (2017).

Yue, X. et al. In situ one-step fabrication of durable superhydrophobic-superoleophilic cellulose/LDH membrane with hierarchical structure for efficiency oil/water separation. Chem. Eng. J. 117–123 (2017). https://doi.org/10.1016/j.cej.2017.07.026.

Li, X. et al. Cyclonic state micro-bubble flotation column in oil-in-water emulsion separation. Sep. Purif. Technol. 165, 101–106 (2016).

Shi, Q. et al. Zwitterionic polyethersulfone ultrafiltration membrane with superior antifouling property. J. Memb. Sci. 319, 271–278 (2008).

Prince, J. A. et al. Ultra-wetting graphene-based PES ultrafiltration membrane—a novel approach for successful oil-water separation. Water Res. 103, 311–318 (2016).

Zhang, R. et al. Antifouling membranes for sustainable water purification: strategies and mechanisms. Chem. Soc. Rev. 45, 5888–5924 (2016).

Aung, A. et al. 3D cardiac µ tissues within a microfluidic device with real-time contractile stress readout. Lab Chip. 16, 153–162 (2016).

Thines, R. K. et al. Application potential of carbon nanomaterials in water and wastewater treatment: a review. J. Taiwan Inst. Chem. Eng. 72, 116–133 (2017).

Ng, L. Y., Mohammad, A. W., Leo, C. P. & Hilal, N. Polymeric membranes incorporated with metal/metal oxide nanoparticles: a comprehensive review. Desalination 308, 15–33 (2013).

Deng, D. et al. Hydrophobic meshes for oil spill recovery devices. ACS Appl. Mater. Interfaces 5, 774–781 (2013).

Zhang, W. et al. Superhydrophobic and superoleophilic PVDF membranes for effective separation of water-in-oil emulsions with high flux. Adv. Mater. 25, 2071–2076 (2013).

Gupta, S. & Tai, N.-H. Carbon materials as oil sorbents: a review on the synthesis and performance. J. Mater. Chem. A. 4, 1550–1565 (2016).

Chen, P. & Xu, Z. Mineral-coated polymer membranes with superhydrophilicity and underwater superoleophobicity for effective oil/water separation. Sci. Rep. 1–6 (2013). https://doi.org/10.1038/srep02776.

Liu, Y. et al. Synergy of the mechanical, antifouling and permeation properties of a carbon nanotube nanohybrid membrane for efficient oil/water separation. Nanoscale 9, 7508–7518 (2017).

Bai, L. et al. Comparison of hydrophilicity and mechanical properties of nanocomposite membranes with cellulose nanocrystals and carbon nanotubes. Environ. Sci. Technol. 51, 253–262 (2017).

Das, R., Ali, M. E., Hamid, S. B. A., Ramakrishna, S. & Chowdhury, Z. Z. Carbon nanotube membranes for water purification: A bright future in water desalination. Desalination 336, 97–109 (2014).

Liu, J. et al. Separation of emulsified oil from oily wastewater by functionalized multiwalled carbon nanotubes. J. Dispers Sci. Technol. 37, 1294–1302 (2016).

Gai, J.-G., Gong, X.-L., Wang, W.-W., Zhang, X. & Kang, W.-L. An ultrafast water transport forward osmosis membrane: porous graphene. J. Mater. Chem. A. 2, 4023 (2014).

Geim, A. K. & Novoselov, K. S. The rise of graphene. Nat. Mater. Naturematerial. 6, 183–191 (2007). https://doi.org/10.1038/nmat1849.

Duan, W. et al. Electrochemical mineral scale prevention and removal on electrically conducting carbon nanotube-polyamide reverse osmosis membranes. Environ. Sci. Proc. Imp. 16, 1300–1308 (2014).

Aghigh, A. et al. Recent advances in utilization of graphene for filtration and desalination of water: a review. Desalination 365, 389–397 (2015).

Cheng, Q., Ye, D., Chang, C. & Zhang, L. Facile fabrication of superhydrophilic membranes consisted of fibrous tunicate cellulose nanocrystals for highly efficient oil/water separation. J. Memb. Sci. 525, 1–8 (2017).

Ajayan, B. P. M., Schadler, L. S., Giannaris, C. & Rubio, A. Single-walled carbon nanotube ± polymer composites: strength and weakness. Adv. Mater. 10, 750–753 (2000).

Ngo, Q. et al. Structural and electrical characterization of carbon nanofibers for interconnect via applications. IEEE Trans. Nanotechnol. 6, 688–695 (2007).

Klein, K. L. et al. Surface characterization and functionalization of carbon nanofibers. J. Appl. Phys. 103, (2008). https://doi.org/10.1063/1.2840049.

Peng, X., Jin, J., Nakamura, Y., Ohno, T. & Ichinose, I. Ultrafast permeation of water through protein-based membranes. Nat. Nanotechnol. 4, 353–357 (2009).

Baker, R. W. Overview of membrane science and technology. Membr. Technol. Appl. 1–14 (2004). https://doi.org/10.1002/0470020393.ch1.

Padaki, M. et al. Membrane technology enhancement in oil-water separation: a review. Desalination 357, 197–207 (2015).

Obaid, M. et al. Effective and reusable oil/water separation membranes based on modified polysulfone electrospun nanofiber mats. Chem. Eng. J. 259, 449–456 (2015).

Zhu, Y., Wang, D., Jiang, L. & Jin, J. Recent progress in developing advanced membranes for emulsified oil/water separation. NPG Asia Mater. 6, e101 (2014).

Zhang, L., Zhang, Z. & Wang, P. Smart surfaces with switchable superoleophilicity and superoleophobicity in aqueous media: toward controllable oil/water separation. NPG Asia Mater. 4, 1–8 (2012).

Kota, A. K., Kwon, G., Choi, W., Mabry, J. M. & Tuteja, A. oil–water separation. Nat. Commun. 3, 1025–1028 (2012).

Zhang, Y., Liu, L. & Yang, F. A novel conductive membrane with RGO/PVDF coated on carbon fiber cloth for fouling reduction with electric field in separating polyacrylamide. J. Appl. Polym. Sci. 133, 1–9 (2016).

Kochkodan, V., Johnson, D. J. & Hilal, N. Polymeric membranes: surface modification for minimizing (bio)colloidal fouling. Adv. Colloid Interface Sci. 206, 116–140 (2014).

Freger, V., Gilron, J. & Belfer, S. TFC polyamide membranes modified by grafting of hydrophilic polymers: an FT-IR/AFM/TEM study. J. Memb. Sci. 209, 283–292 (2002).

Tarabara, V. V. Multifunctional nanomaterial-enabled membranes for water treatment. (eds Street, A., Sustich, R., Duncan, J. & Savage, N.). In Nanotechnology Applications for Clean Water, 2nd edn. 155–171 (Elsevier, Oxford, 2014).

Pendergast, M. M. & Hoek, E. M. V. A review of water treatment membrane nanotechnologies. Energy Environ. Sci. 4, 1946 (2011).

Nation, U. Separation and purification technology carbon nanotube membranes for water purification: developments, challenges, and prospects for the future. Sep. Purif. Technol. 209, 307–337 (2019).

Sianipar, M., Kim, S. H., Iskandar, F. & Wenten, I. G. Functionalized carbon nanotube (CNT) membrane: progress and challenges. R. Soc. Chemstryyal Soc. Chem. 7, 51175–51198 (2017).

Jayaramulu, K. et al. Biomimetic superhydrophobic/superoleophilic highly fluorinated graphene oxide and ZIF-8 composites for oil-water separation. Angew. Chem. – Int. Ed. 55, 1178–1182 (2016).

Li, J. et al. Development of a measurement and control system for a 40l/h helium liquefier based on Siemens PLC S7-300. Phys. Procedia 67, 1181–1186 (2015).

Gilje, S. et al. Processable aqueous dispersions of graphene nanosheets. Nat. Nanotechnol. 3, 101–105 (2008).

Huang, Y. et al. Ultrafiltration membranes with structure-optimized graphene-oxide coatings for antifouling oil/water separation. Adv. Mater. Interfaces. 2, (2015). https://doi.org/10.1002/admi.201400433.

Li, H. et al. Ultrathin, molecular-sieving graphene oxide membranes for selective hydrogen separation. Science 342, 95–98 (2013).

Lee, C., Wei, X., Kysar, J. W. & Hone, J. Measurement of the elastic properties and intrinsic strength of monolayer graphene. Sci. Mag. 321, 385–388 (2008).

Chen, H., Müller, M. B., Gilmore, K. J., Wallace, G. G. & Li, D. H. Mechanically strong, electrically conductive, and biocompatible graphene paper. Adv. Mater. 20, 3557–3561 (2008).

Liu, N. et al. Ultralight free-standing reduced graphene oxide membranes for oil-in-water emulsion separation. J. Mater. Chem. A. 3, 20113–20117 (2015).

Hu, X. et al. The improved oil/water separation performance of graphene oxide modified Al2O3 microfiltration membrane. J. Memb. Sci. 476, 200–204 (2015).

Liu, G., Jin, W. & Xu, N. Graphene-based membranes. R. Soc. Chemstryyal Soc. Chem. 5016–5030 (2015). https://doi.org/10.1039/c4cs00423j.

Chen, D. Feng, H. & Li, J. Graphene oxide: preparation, functionalization, and electrochemical applications. Chem. Rev. (2012). https://doi.org/10.1021/cr300115g.

Hirsch, P. A. et al. Chemical functionalization and characterization of graphene-based materials. R. Soc. Chemstryyal Soc. Chem. (2017). https://doi.org/10.1039/c7cs00229g.

Kuila, T., Bose, S., Kumar, A. & Khanra, P. Progress in materials science chemical functionalization of graphene and its applications. Prog. Mater. Sci. 57, 1061–1105 (2012).

Luhyna, N. & Inam, F. Carbon nanotubes for epoxy nanocomposites: a review on recent developments. (eds Day, R. & Reznik, S.) In: Second International Conference on Advanced Composite Materials Technology and Aerospace Applications. 11–13 (Wrexham: 2012).

Gao, S. J., Shi, Z., Bin W. Z., Zhang, F. & Jin, J. Single-walled carbon nanotube/TiO2 ultrathin network films for ultrafast separation of oil-in-water emulsions. (2014). https://doi.org/10.1021/nn501851a.

Gao, C. et al. Integrated oil separation and water purification by a double-layer TiO2-based mesh. Energy Environ. Sci. 6, 1147–1151 (2013).

Chakrabarty, B., Ghoshal, A. K. & Purkait, M. K. Ultrafiltration of stable oil-in-water emulsion by polysulfone membrane. J. Memb. Sci. 325, 427–437 (2008).

Lobo, A., Cambiella, Á., Benito, J. M., Pazos, C. & Coca, J. Ultrafiltration of oil-in-water emulsions with ceramic membranes: influence of pH and crossflow velocity. J. Memb. Sci. 278, 328–334 (2006).

Te Hsieh, C., Hsu, J. P., Hsu, H. H., Lin, W. H. & Juang, R. S. Hierarchical oil-water separation membrane using carbon fabrics decorated with carbon nanotubes. Surf Coat. Technol. 286, 148–154 (2016).

Hu, L. et al. Photothermal-responsive single-walled carbon nanotube-based ultrathin membranes for on/off switchable separation of oil-in-water. ACS Nano. 9, 4835–4842 (2015).

Saadati, J. & Pakizeh, M. Separation of oil/water emulsion using a new PSf/pebax/F-MWCNT nanocomposite membrane. J. Taiwan Inst. Chem. Eng. 71, 265–276 (2017).

Gu, J. et al. Robust preparation of superhydrophobic polymer/carbon nanotube hybrid membranes for highly effective removal of oils and separation of water-in-oil emulsions. J. Mater. Chem. A. 2, 15268 (2014).

Mandal, S. et al. Designer carbon nanotubes for contaminant removal in water and wastewater: a critical review. Sci. Total Environ. 612, 561–581 (2017).

Ma, L. et al. Fabrication and water treatment application of carbon nanotubes (CNTs)-based composite membranes: a review. Membranes (Basel) 7, (2017). https://doi.org/10.3390/membranes7010016.

Zhu, X. et al. Field-induced redistribution of surfactants at the oil/water interface reduces membrane fouling on electrically conducting carbon nanotube UF membranes field-induced redistribution of surfactants at the oil/water interface reduces membrane fouling on. Environ. Sci. Technol. (2018). https://doi.org/10.1021/acs.est.8b02578.

Sholl, D. S. & Johnson, J. K. Making high-flux membranes with carbon nanotubes. Science 312, 1003–1005 (2006).

Gethard, K., Sae-khow, O. & Mitra, S. Water desalination using carbon-nanotube-enhanced membrane distillation. ACS Appl. Mater. Interfaces. 3, 110–114 (2011).

Zhang, X. & Yang, Z. Enhanced water flux in vertically aligned carbon nanotube arrays and polyethersulfone composite membranes. R. Soc. Chemstryyal Soc. Chem. 2, (2014). https://doi.org/10.1039/c4ta02119c.

Das, R. et al. Carbon nanotube membranes for water puri fi cation: a bright future in water desalination. DES 336, 97–109 (2014).

C., M. et al. Robust superhydrophobic carbon nanofiber network inlay-gated mesh for water-in-oil emulsion separation with high fl ux., J. Mater. Chem. A Mater. Energy Sustain. 4, 17970–17980 (2016).

In-Yup Jeon, D. W. C., Kumar, N. A. & Baek, J-B. Functionalization of Carbon Nanotubes, Carbon Nanotubes – Polymer Nanocomposites, (Yellampalli, S. ed.), InTech (2011). Available from: http://www.intechopen.com/books/carbon-nanotubes-polymer-nanocomposites/functionalization-of-carbon-nanotubes.

Liu, H. et al. Flexible macroporous carbon nanofiber film with high oil adsorption capacity. J. Mater. Chem. A. 2, 3557 (2014).

Tai, M. H.et al. Highly efficient and flexible electrospun carbon–silica nano fibrous membrane for ultrafast gravity-driven oil–water separation. Appl. Mater. Interfaces (2014). https://doi.org/10.1021/am501758c.

Al-Saleh, M. H. & Sundararaj, U. Review of the mechanical properties of carbon nanofiber/polymer composites. Compos. Part A Appl. Sci. Manuf. 42, 2126–2142 (2011).

Hammel, E. et al. Carbon nanofibers for composite applications. Carbon N. Y. 42, 1153–1158 (2004).

Zhang, J., Xue, Q., Pan, X., Jin, Y., Lu, W., Ding, D. & Guo, Q. Graphene oxide/polyacrylonitrile fiber hierarchical-structured membrane for ultra-fast microfiltration of oil-water emulsion. Chem. Eng. J. 307, 643–649 (2017). https://doi.org/10.1016/j.cej.2016.08.124.

Zhu, H., Qiu, S., Jiang, W., Wu, D. & Zhang, C. Evaluation of electrospun polyvinyl chloride/polystyrene fibers as sorbent materials for oil spill cleanup. Environ. Sci. Technol. 45, 4527–4531 (2011).

Shang, Y. et al. An in situ polymerization approach for the synthesis of superhydrophobic and superoleophilic nanofibrous membranes for oil–water separation. Nanoscale 4, 7847 (2012).

Liu, Y. et al. Asymmetric aerogel membranes with ultrafast water permeation for the separation of oil-in-water emulsion. ACS Appl. Mater. Interfaces 10, 26546–26554 (2018).

Abraham, S., Kumaran, S. K. & Montemagno, C. D. Gas-switchable carbon nanotube/polymer hybrid membrane for separation of oil-in-water emulsions. RSC Adv. 7, 39465–39470 (2017).

Jiang, Y., Hou, J., Xu, J. & Shan, B. Switchable oil/water separation with efficient and robust Janus nanofiber membranes. Carbon N. Y. (2017). https://doi.org/10.1016/j.carbon.2017.01.053.

Sun, J. et al. One-step preparation of GO/SiO2 membrane for highly efficient separation of oil-in-water emulsion. J. Memb. Sci. 553, 131–138 (2018).

Peng, Y. & Guo, Z. Recent advances in biomimetic thin membranes applied in emulsified oil/water separation. J. Mater. Chem. A. 4, 15749–15770 (2016).

Hu, L. et al. An ultrathin bilayer membrane with asymmetric wettability for pressure responsive oil/water emulsion separation. J. Mater. Chem. A. 3, 23477–23482 (2015).

Chen, J. et al. Highly efficient and robust oil/water separation materials based on wire mesh coated by reduced graphene oxide. Langmuir 33, 9590–9597 (2017).

Guo, G., Liu, L., Zhang, Q., Pan, C. & Zou, Q. Solution-processable, durable, scalable, fluorine-grafted graphene-based superhydrophobic coating for highly efficient oil/water separation under harsh environment. New J. Chem. 42, 3819–3827 (2018).

Hang, M., Juay, J., Sun, D. D. & Leckie, J. O. Carbon – silica composite nanofiber membrane for high flux separation of water-in-oil emulsion—Performance study and fouling mechanism. Sep. Purif. Technol. 156, 952–960 (2015). https://doi.org/10.1016/j.seppur.2015.08.008.

Liu, Y. et al. A mussel-induced method to fabricate reduced graphene oxide/halloysite nanotubes membranes for multifunctional applications in water purification and oil/water separation. Chem. Eng. J. 336, 263–277 (2018).

Peng, Y. et al. A novel reduced graphene oxide-based composite membrane prepared via a facile deposition method for multifunctional applications: oil/water separation and cationic dyes removal. Sep. Purif. Technol. 200, 130–140 (2018).

Zhu, Y., Chen, P. & Nie, W. Greatly Improved Oil-in-Water Emulsion Separation Properties of Graphene Oxide Membrane upon Compositing with Halloysite Nanotubes. Water, Air, Soil Pollut. 229, 94 (2018). https://doi.org/10.1007/s11270-018-3757-6.

Liu, Y. et al. 2D Heterostructure membranes with sunlight-driven self-cleaning ability for highly efficient oil–water separation. Adv. Funct. Mater. 28, 1–10 (2018).

Wu, Z., Zhang, C., Peng, K., Wang, Q. & Wang, Z. Hydrophilic/underwater superoleophobic graphene oxide membrane intercalated by TiO2 nanotubes for oil/water separation. Front. Environ. Sci. Eng. 12, 15 (2018).

Chen, Q. et al. A novel photocatalytic membrane decorated with RGO-Ag-TiO2 for dye degradation and oil–water emulsion separation. J. Chem. Technol. Biotechnol. 93, 761–775 (2018).

Naseem, S., Wu, C. M., Xu, T. Z., Lai, C. C. & Rwei, S. P. Oil-water separation of electrospun cellulose triacetate nanofiber membranes modified by electrophoretically deposited TiO2/graphene oxide. Polymers (Basel). 10, (2018). https://doi.org/10.3390/polym10070746.

Ding, G. et al. Ultrafast, reversible transition of superwettability of graphene network and controllable underwater oil adhesion for oil microdroplet transportation. Adv. Funct. Mater. 28, 1–11 (2018).

Qian, D. et al. TiO2/sulfonated graphene oxide/Ag nanoparticle membrane: in situ separation and photodegradation of oil/water emulsions. J. Memb. Sci. 554, 16–25 (2018).

Zhan, Y. Thermally and chemically stable poly (arylene ether nitrile)/halloysite nanotubes intercalated graphene oxide nano fi brous composite membranes for highly efficient oil/water emulsion separation in harsh environment. J. Memb. Sci. 567, 76–88 (2018).

Santosh, V., Gopinath, J., Veera Babu, P., Sainath, A. V. S. & Reddy, A. V. R. Acetyl-D-glucopyranoside functionalized carbon nanotubes for the development of high performance ultrafiltration membranes. Sep. Purif. Technol. (2017). https://doi.org/10.1016/j.seppur.2017.09.018.

Saththasivam, J. et al. Architecture for carbon nanotube membranes towards fast and efficient oil/water separation. Sci. Rep. 8, 4–9 (2018).

Zhang, L. et al. Designing a reductive hybrid membrane to selectively capture noble metallic ions during oil/water emulsion separation with further function enhancement. J. Mater. Chem. A. 6, 10217–10225 (2018).

Gu, J. et al. Journal of colloid and interface science sandwich-structured composite fibrous membranes with tunable porous structure for waterproof, breathable, and oil-water separation applications. J. Colloid Interface Sci. 514, 386–395 (2018).

Santosh, V., Gopinath, J. & Veera, P. Separation and purification technology acetyl-D-glucopyranoside functionalized carbon nanotubes for the development of high performance ultra fi ltration membranes. Sep. Purif. Technol. 191, 134–143 (2018).

Lin, X. et al. Cobweb-inspired superhydrophobic multiscaled gating membrane with embedded network structure for robust water-in-oil emulsion separation. ACS Sustain. Chem. Eng. 5, 3448–3455 (2017).

Source: Resources - nature.com