The experiment was performed in a commercial area of the Agrodoce Agricultural Group at Boracéia-SP, Brazil, during 2016 to 2018. The location of the experimental area is 22°11’ S and 48°48’ W at 480 m altitude. According to the Köppen classification, the predominant climate in the region is Cwa, which is mainly tropical humid with a hot summer. The soil was classified as a sandy-textured Typic Hapludox18. Chemical and physical characterizations19 were obtained from air-dried soil samples (0–0.20 and 0.20–0.40-m layers) passed through a 2-mm sieve (10 mesh) and showed the following results: Surface layer (sand, 705; clay, 48 and silt, 246 g kg−1); 5.6 pH (CaCl2); 16 g dm−3 organic matter; 9 mg dm−3 Presin; 1.1, 27, 10, and 15 mmolc dm−3 of exchangeable K, Ca, Mg, and H + Al, respectively; and a base saturation (BS) of 71%. For the subsurface layer (sand, 702; clay, 41 and silt, 256 g kg−1); 5.3 pH (CaCl2); 10 g dm−3 organic matter; 14 mg dm−3 Presin; 0.54, 21, 07, and 18 mmolc dm−3 of exchangeable K, Ca, Mg, and H + Al, respectively; and a base saturation (BS) of 61%.

A randomized block experimental design was established with four replicates using a 2 × 5 factorial scheme. The treatments consisted of two sources (mineral and organomineral fertilizers) applied at 5 rates as follows: 05–25–25 (N-P-K), commercial mineral fertilizer grade composed by monoammonium phosphate (MAP, 460 kg t−1), single superphosphate (SSP, 110 kg t−1) and muriate of potash (KCl, 430 kg t−1) at rates 0; 240 kg ha−1 (N, 12; P2O5, 60 and K2O, 60 kg ha−1); 480 kg ha−1 (N, 24; P2O5, 120 and K2O, 120 kg ha−1); 600 kg ha−1 (N, 30; P2O5, 150 and K2O, 150 kg ha−1) and 720 kg ha−1 (N, 36; P2O5, 180 and K2O, 180 kg ha−1) and Organomineral fertilizer, composed by MAP (288 kg t−1), KCl (250 kg t−1) and an granulated organic matrix (462 kg t−1)at rates of 0; 400 kg ha−1 (N, 12; P2O5, 60 and K2O, 60 kg ha−1); 800 kg ha−1 (N, 24; P2O5, 120 and K2O, 120 kg ha−1); 1000 kg ha−1 (N, 30; P2O5, 150 and K2O, 150 kg ha−1) and 1200 kg ha−1 (N, 36; P2O5, 180 and K2O, 180 kg ha−1). These treatments were established in February 2016 (plant cane) and the fertilizers were applied in the planting furrow bottom, 0.2–0.3 m deep. For 2018 (first ratoon), a single rate of 170 kg ha−1 for N and K was applied for all plots aiming to supply the nutrient exportation by the mean sugarcane yield of the first crop season and not to be an interference factor in the ratoon yield, making it possible to evaluate the residual effect of the applied fertilizer on the cane plant. As source of N and K were used KCl (333 kg t−1) and ammonium nitrate (606 kg t−1) and an organomineral [composed by urea (325 kg t−1), KCl (233 kg t−1) and a granulated organic matrix (442 kg t−1)] for mineral and organomineral plots, respectively. Each plot consisted of 4 double-rows (2.4 × 0.9 m) 20 m in length disregarding the 0.5-m edge at each end.

The organomineral fertilizer is a commercial grade fertilizer manufactured at Solvi group fertilizer industry located in Coroados, São Paulo, Brazil (21°23’07.1”S 50°15’15.0”W), commercialized under the name of Organosolvi® and is openly available to customers on www.organosolvi.com. The organic matrix of the organomineral is originated from the agroindustries located near the fertilizer plant, and is composed by byproducts of meat industry (rumen, blood, bones), dairy products, Fuller’s earth (high absorbent and high CEC clay minerals used in the tallow industry), pine bark and eucalyptus. Before its use for organomineral production, it is submitted to a composting process. After composting its chemical composition showed the following results, in g kg−1, 177 of OC, 23 of N, 16 of P2O5, 18 of K2O, 23 of Ca, 5.0 of Mg, 5.0 of S and, in mg kg−1, 148 of Zn, 27 of Cu, 416 of Mn, 10.000 of Fe, 600 of B and a moisture of 24.2%, pH (CaCl2) = 8.1 and CEC = 607.2 mmolc kg−1. Then, the compost is sent to a rotating drum that consists of shaping and sphericity, and then to a rotary dryer with a hot air flow (120 °C). After drying, the granules were classified in sieves of 1 to 4 mm, acquiring a granulometry very similar to the standard mineral fertilizer. Following this process, it was mixed with mineral fertilizers (MAP, KCl and urea treated with a nitrification inhibitor + polymer-based additive that controls the N availability and minimizes N losses via volatilization). The nitrogen sources used in mineral fertilization (MAP for plant cane and ammonium nitrate for ratoon) are not likely to lose N by volatilization due to the low pH resulted of their dissolution20,21,22,23. Thus the N amount supplied by both organomineral and mineral fertilizers would be the same, allowing to evaluate the organic matter matrix effect regardless the N losses from nitrogen sources. Urea has a high N content (45%), thus this is the best N source for organomineral fertilizer because it allows increasing the N content in it with the smallest increment in its final mass.

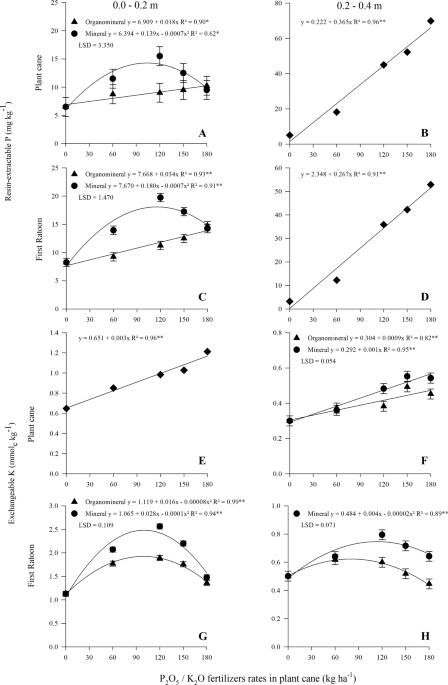

Following 6 months of treatment application, a period of full vegetative growth of sugarcane, 10 +1 leaves or TVD (Top Visible Dewlap leaf), were collected within each plot in the two central rows according to the numbering system suggested by Kuijper24. Disregarding the leaf midrib and considering only the middle third of the leaf blade, the material was dried in an oven with forced air circulation at 60 °C until a constant mass was obtained. It was then milled and leaf N, P and K contents were determined25. Prior to harvest, the stalk number m−1 was determined by counting the stalks in the two central rows within the useful area of each plot and then converting to the number of stalks m−1. Stalk weight, diameter, plant height, internode number and length were calculated as the means of the ten stems collected from each plot, clipped at the apical bud height, defoliated and measured using a digital scale, caliper and a ruler marked in meters from the soil surface up to the auricle region of the +1 or TDV leaf. After the growth evaluations, the cleaned stalks were sent to the Middle Tietê Sugarcane Planters Association (ASCANA) Laboratory, in Lençóis Paulista, SP, Brazil for processing according to the methodology defined in the Sucrose Content-Based Sugarcane Payment System, in accordance with Consecana’s semiannual updates for the technological evaluations as described by Fernandes26. At harvesting, the four central rows of each plot were mechanically harvested and stalks were weighed using an electronic load cell. Then, the stalk yield was estimated extrapolating the values to stalk yield ha−1, disregarding planting holes (gaps greater than 0.5 m). Sugar yield ha−1 was estimated as the product of the multiplication of the sucrose concentration (%) and stalk yield (Mg ha−1) at harvest. Following harvest, soil samples were collected at depths of 0.00–0.20 and 0.20–0.40 m in all plots using a Dutch auger. Five subsamples were randomly collected in planting row of each plot and combined into a composite sample. Soil chemical attributes were determined following the method of Raij et al.19.

The agronomic efficiency index (AEI)27 and the economic efficiency index (EEI) were calculated as the percentage ratio between the stalk and sugar yields (AEI) and net profits (EEI) resulting from the mineral and organomineral fertilizers applied at the same rate in the plant cane and the residual effect in first ratoon. For AEI, the crop yield obtained in the treatment control was subtracted from both yields as follows (Eq. 1):

$$mathrm{AEI}( % )=[({rm{Y}}2-{rm{Y}}1)/({rm{Y}}3-{rm{Y}}1)]times 100$$

(1)

where Y1 = crop yield in the control treatment; Y2 = crop yield using organomineral fertilizer at the corresponding rate; and Y3 = crop yield with mineral fertilizer at the corresponding rate.

For EEI, the percentage ratio of the net profits obtained for both fertilizers was obtained by Eq. 2:

$${rm{EEI}}( % )=({rm{X}}2/{rm{X}}1)times 100$$

(2)

where X2 = net profit using organomineral fertilizer at the corresponding rate and X1 = net profit using mineral fertilizer at the corresponding rate. The net profit was calculated using the Eq. 3:

$${rm{Net}},{rm{profit}}(text{US}$,{{rm{ha}}}^{-1})={rm{Revenue}},mbox{–},{rm{Fertilizers}},{rm{cost}}$$

(3)

The revenue and fertilizers cost were converted using dollar quotation at each respective time (harvests, September 2017 and 2018; planting fertilization, February 2016 and first ratoon fertilization, October 2017). The revenue was obtained using the Eq. 4:

$${rm{Revenue}}(text{US}$,{{rm{ha}}}^{-1})=(({rm{Value}},{rm{of}},{rm{TRS}}times {rm{sugarcane}},{rm{TRS}})times ({rm{stalk}},{rm{yields}}))$$

(4)

The total economic efficiency index (EEI total) was estimated similarly to the EEI, but using the sum of net profit of plant cane and first ratoon.

Data for each crop season were separately subjected to analysis of variance. The fertilizer source means were compared using the t test (LSD) at 5% probability. The rate effects were evaluated via regression analysis using the statistical software package SISVAR28.

Source: Ecology - nature.com